The Phase 1: Analysis and planning

The objectives: Clarifying various issues related to dealing the overall complexity of the target system, processing of big data streams from large number of meters, automated systems and other optional data sources in real time and enabling effective support of operators and management running the applications in sustainable industrial and urban environments.

During the phase the integrators collect the necessary information about each automated system to be integrated, its structure, protocols, data sources, probe interrogation rate in relation to target physical process, formulation of the process control targets, etc. The work shall address high level functional and technical requirements received from the customer including definitions provided by management and operators who need to be assisted with high level information services and controls.

The phase shall result in complete set of requirements, high level system specifications and implementation plans that clarify technical issues and provide reliable estimation of time schedule as well as necessary additional equipment and development costs.

The results may include the follow details:

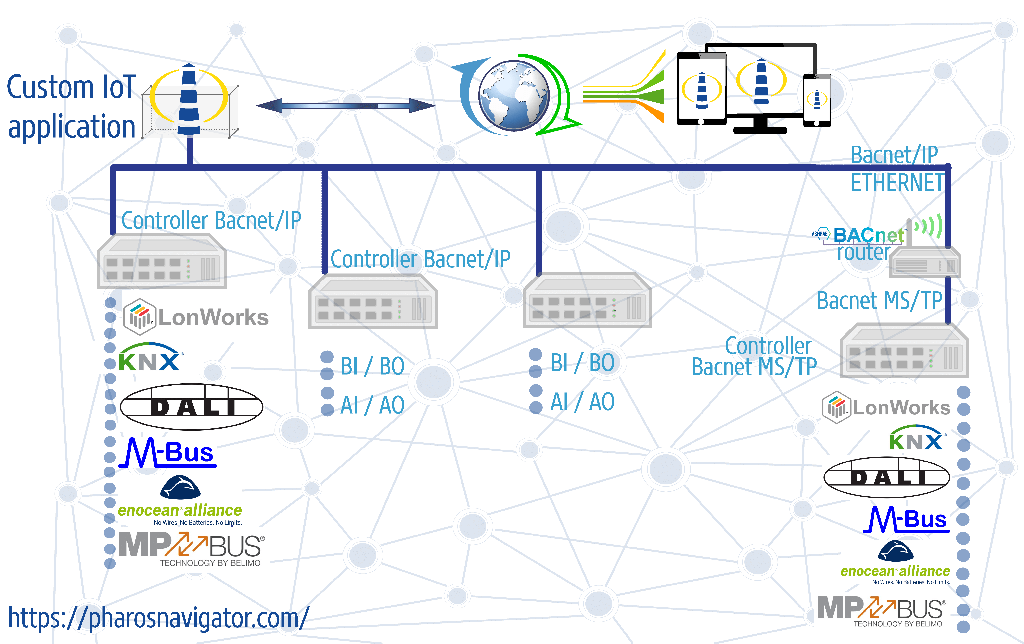

1. Secure linking options to each automated system (e.g. SQL DB, BCXs, HVAC-AHU-EF, Power meters, pumps, Chillers MetaSys ADS, etc).

2. Defining data stream properties by each sub-system

3. Formulating the overall structure of the heterogeneous system and its properties to be monitored and controlled

4. Defining the indicators and targets for each measured process that are required by the customer operators and management based on the available data for each main system component

5. Formulating optional statuses for system objects to be monitored and analysed and relevant operator response options

6. Describing requirements for analytics, events and alarms that management and operators need in real world use cases for further implementation in customer specific GUI dashboards, reports, widgets and mobile apps to be linked to the customer IoT Integra system

7. Evaluation of measures to ensure necessary levels of security and data protection in the customer application system taking into consideration solutions that already are implemented in PharosN platform (open source standards).

The Phase 2: System implementation and QA testing

Based on in-depths analysis of Phase 1 and using the PharosN interactive tools, the integrators develop the application model of target cyber-physical system and link it to all necessary data sources and test the integrated software solution running the model. The open hierarchical structure of the model will enable easy further adaptation and tuning during the system implementation and testing.

The Phase 1 specifications will be used for making custom dashboards and reports and apps (IOS & Android) supporting managerial and operator tasks.

The complete IoT integrated solution (named by the integrators) will provide complex monitoring and holistic sustainability and cause analytics functions for the integrated system as well as all required sub-systems.

Software and hardware requirements for Phase 2 implementation

There are no special additional requirements and costs for the implementing IoT Integra software solutions. PharosN architecture includes all necessary components for its immediate running in cloud engine or installation and running at premises on dedicated HW server. The dedicated HS installation would require setting Ubuntu server, docker and integrated PharosN package that already include major well known open source components.

Project milestones for Phase 2

The anticipated milestones depend on the complexity of the target application solution. It can be estimated as follows:

1. Development of the system application model: 1-2 weeks

2. Linking the model to data sources and systems: 1-2 weeks

3. Application tuning to customer monitoring targets and definitions of sustainability: 1 week

4. Customising the dashboards, reports and linking to mobile apps: 1-2 weeks

5. Final system verification and presentation to customer: up to 1 week

Final product

1. Runs in real time providing integrated both holistic and detailed views and analytics for the ongoing processes in both subsystems for management and operators

2. Has copyrights of the integrators

3. Can be replicated by the developers and sold to different customers

4. Administered independently by developers or their customers

5. Runs on PharosN platform (hosting analogue) being updated and improved by GOLEM IMS GMBH

Upgrading

PharosN platform will support high-level controlling / actuations functions along with the advanced reporting & analytics modules and AI-driven methods (machine learning, condition monitoring and maintenance predictions, prescriptive analytics and neural networks) and 3D AR/VR to enable advanced assistance to management and operators and high level of operational performance.

After the implementation the integrator cane further embedd the customised solutions into Linux-powered Raspberry Pi-like computers to create complex intelligent distributed custom applications.